Luminal communication networks. While perhaps not to grandiose scales in physical terms, the information networks we have built over the past three decades rank among the most advanced infrastructure in history.[17] In the United States, however, these networks are becoming ever-more dated. While corporate monopolies and broken politics certainly don’t help,[18] the primary problem is one of distance. The vastness of the United States presents challenges to providing high-speed internet nationwide at low cost – costs that have to be paid over and over again once outdated technology needs to be updated.

As we saw throughout much of this writing, municipally integrated renewables and the National Aqueduct provide ample opportunity to run utility lines, including those for communication. This gives us a natural platform to run internet cables over any distance effectively, as their generated electricity could power amplification systems to prevent signal loss. And instead of traditional cables that transfer data through copper wires, we can now install fiber-optic cables that are 30-100 times faster.[19]

If internet service were embedded throughout renewable-integrated highway networks and the National Aqueduct, we’d effectively turn the country into a giant antenna. This process further becomes more cost-effective, because running fiber cables through above-ground conduits is far easier and less expensive than today’s method of running cables underground. If municipal internet were provided through road networks and the National Aqueduct, we would effectively have nationwide wireless internet, low in cost an expansive in scale – cementing a next-generation information backbone for everyone in society.

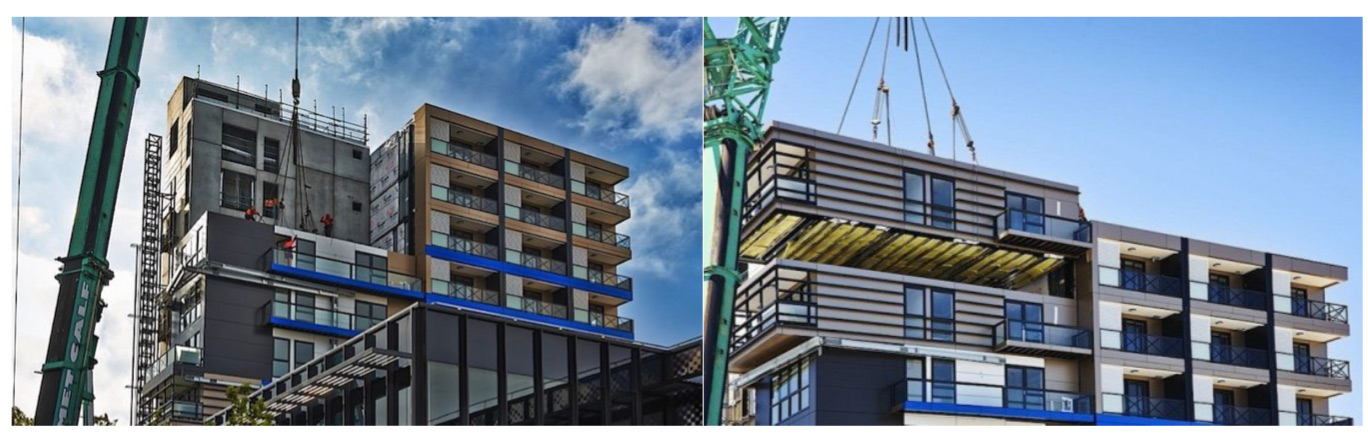

Prefabricated buildings. We’ve so far talked at length about the concepts of prefabrication and 3D-printing, with attention to how we can use them to build advanced systems quicker, better, and with less expense. Megatunnels and megabridges are good examples of how we can apply these concepts to larger-scale infrastructure, but there are also other promising applications – such as extending residential prefabrication beyond what we saw last chapter. The following three images show the “One9,” a nine-story prefabricated apartment building in Melbourne, Australia that was installed in just five days.[20]

This apartment complex in Kansas City features 80 modular units that was finish-assembled on-site within four months:[21]

For comparison, the average time to construct a single-family home in the United States is between 6-11 months, once a building permit is issued.[22] Prefabricated structures such as these are attractive options for reducing housing shortages, a problem that is expected to increase as large numbers of people continue to migrate to cities.[23]

Prefabrication also works on even larger scales. We saw in Chapter Eleven how China’s Broad Sustainable Buildings assembled a 30-story tower in 15 days. But that’s only a pioneering example of the potential of prefabricated structures. The company has since outdone themselves by building a 57-story skyscraper in nineteen days, which, at three stories per day, is 33% faster than their previous performance. Named “J57 Mini Sky City,” the structure is one of the tallest modular buildings in the world.

Back in the United States, Skanska, a Swedish construction company, has recently completed “461 Dean,” a 363-unit apartment building in downtown Brooklyn. The 32-story building, completed in approximately 18 months, saved 20% on construction costs when compared to traditional building methods.[24]

These cost savings are then passed on to prospective tenants, as the studio units in this building start at $560/month in a neighborhood where the median rent is roughly $2,700.[25]

When we consider the reduced costs and shorter construction timelines on these buildings, it’s important to be mindful that they represent the first variants of this emerging technology. Further, these feats of engineering are also performed with today’s technology and material limitations. If we think about how far we've come in other areas over just the last 20-30 years, there's no telling how much more advanced this type of construction can become in the future – especially if the advances of Scarcity Zero were incorporated.