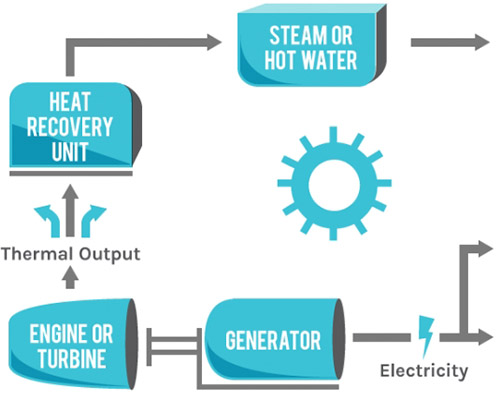

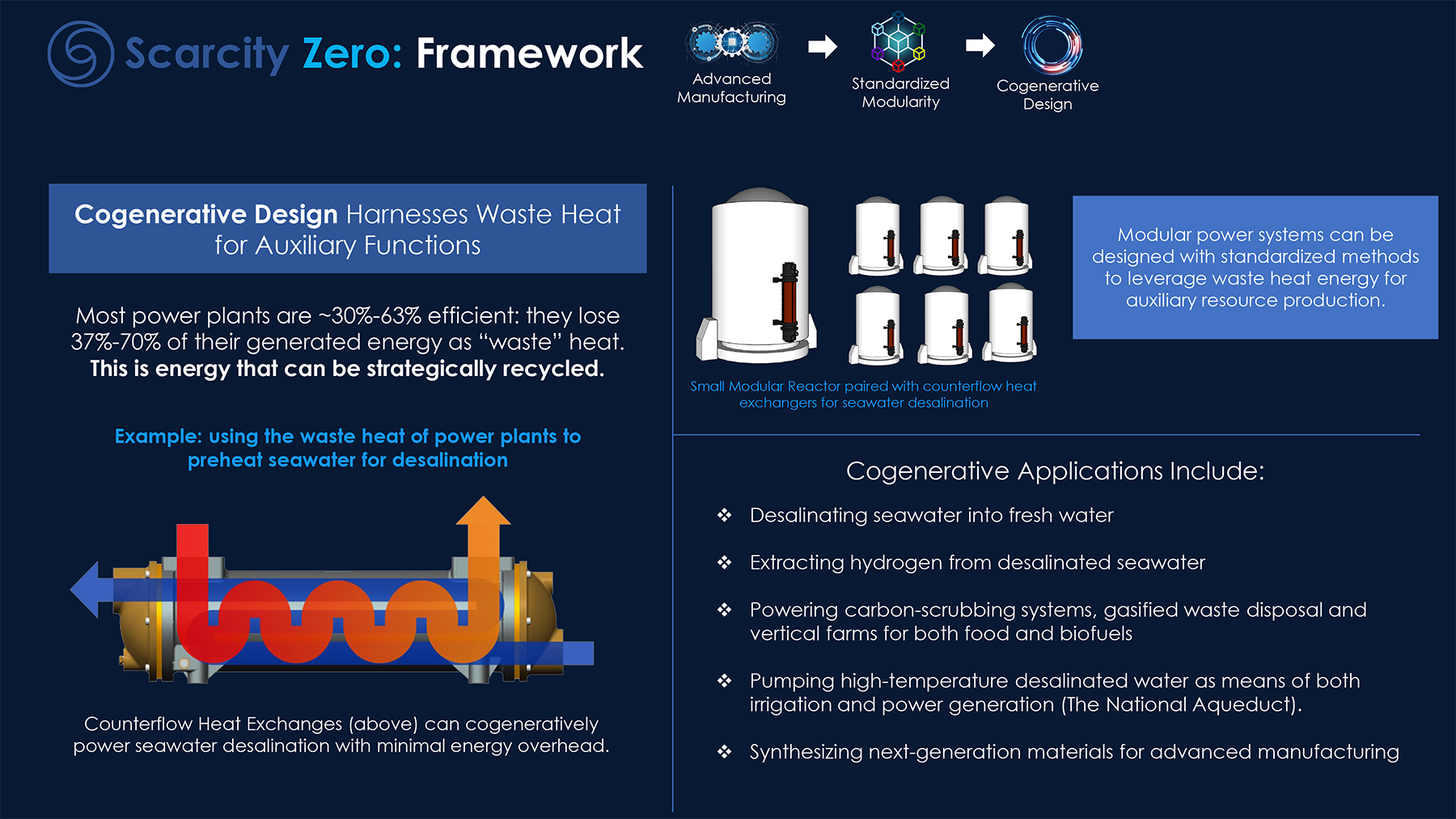

The driving mindset behind Scarcity Zero's deployment strategy is cooperation by design. This means all technologies are designed to interact seamlessly with each other as an team that is greater than the sum of its individual parts. Of the most effective ways to do this is to leverage the waste energy of one technology to help power the functions of another. This concept is known as cogeneration - or Combined Heat and Power - and it is common in modern system design to varying degrees.

Yet this is less true when it comes to our power and resource infrastructure.

By and large, our current power infrastructure is just "there" - decentralized, ad-hoc systems that are custom-designed, built to order and deployed without adherence to a streamlined or standardized nationwide power strategy. Consequently, the ability of these systems to work together is limited - all the more so since they use non-standardized components and fuels, and are owned by a wide array of competing private and public entities. Just as importantly: the energy they generate is usually only used for electricity. Any excess heat generated is written off as "waste" instead of harnessed for auxiliary functions.

It is difficult to overstate the opportunity cost incurred by this mistake.

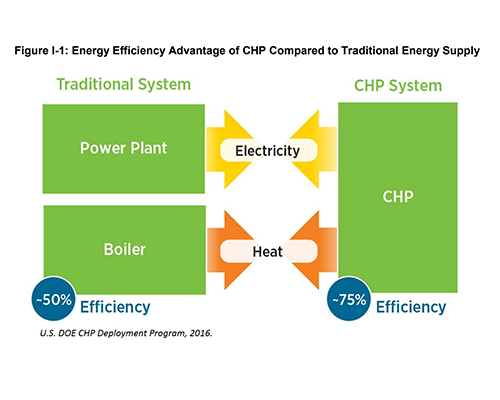

Many power plants today have an efficiency of around 33%.[4] This means 67% of their generated energy is wasted, usually in the form of heat that either dissipates into the surrounding air or is absorbed into the ground. That is effectively twice the energy used to generate electricity in the first place. It stands to reason, then, how much energy we could be recapturing for other purposes through improvements in system design.

This reality is not lost on organizations dedicated to improving energy efficiency, which have employed cogenerative design in recent projects. Even if the instances are comparatively limited, the practice has proven highly effective for supplemental resource production.

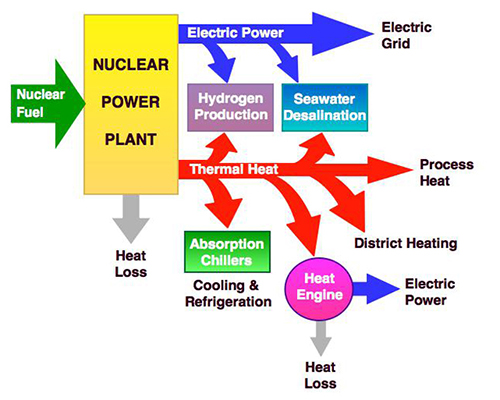

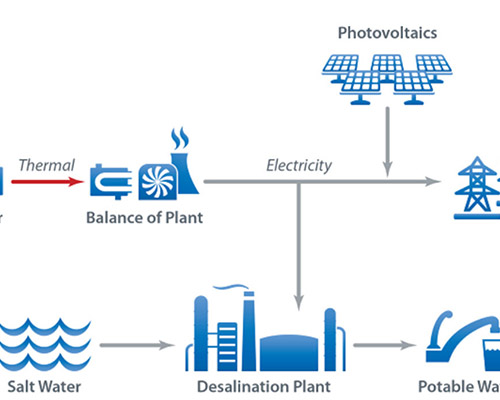

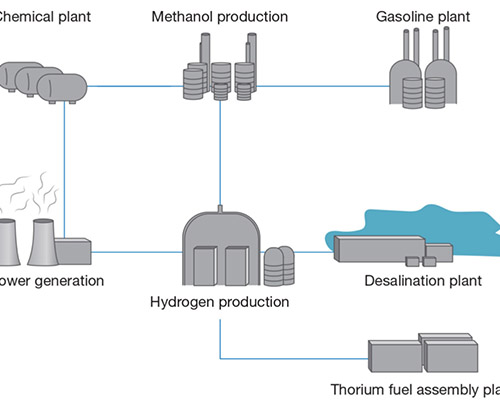

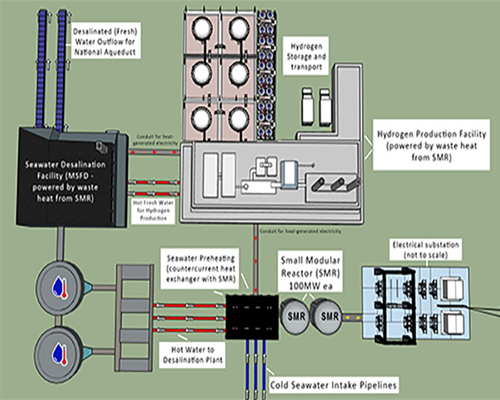

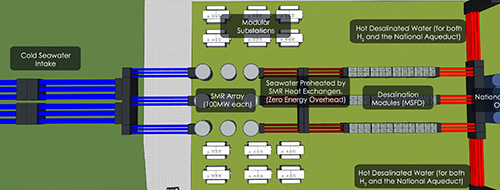

One notable example is the National Renewable Energy Laboratory's REopt™ model (Renewable Energy Integration & Optimization), which is designed to identify renewable and/or efficient energy opportunities within various technologies, energy requirements and constraints. Their model is extended through hundreds of projects nationwide to build resilient microgrids, energy storage systems and water treatment facilities. One of their flagship projects in Arizona involved the optimized integration of a nuclear reactor with renewables to efficiently and cost-effectively desalinate seawater into hydrogen. Another example is China's TSMR project in Gansu province. Their cogenerative deployment leverages up to 100 megawatts of clean energy to power resource-producing systems within fresh water, hydrogen fuel and chemical hydrocarbons.

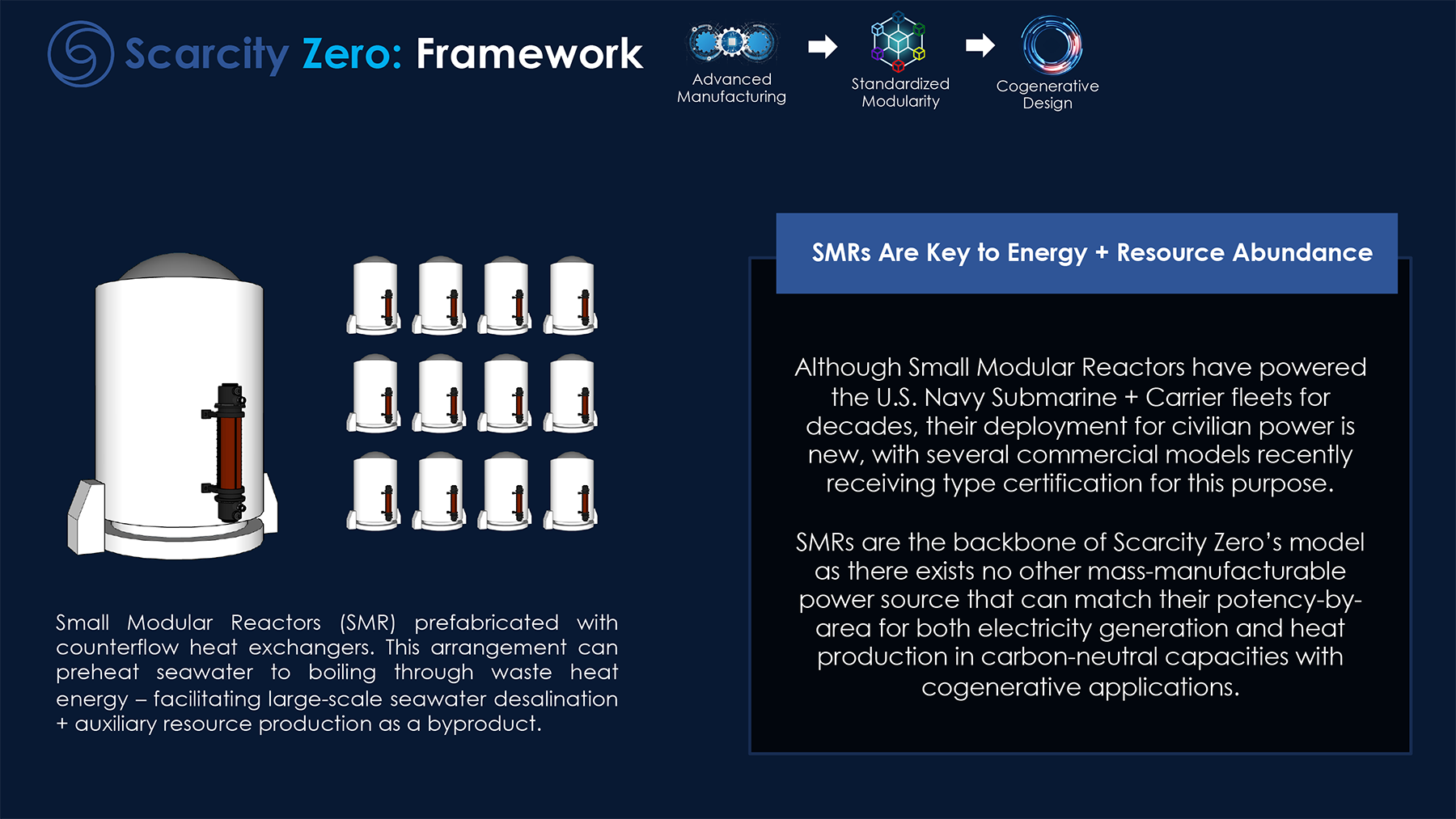

Yet a critical drawback to these projects is that they are limited by manufacturing approaches. Cogenerative design can be employed in practically any energy system, but if they are built as unique, non-standardized entities, any utility - and all attendant expertise - can only be realized in those systems. Everything needs to be done again from scratch if the effort needs to be replicated elsewhere.

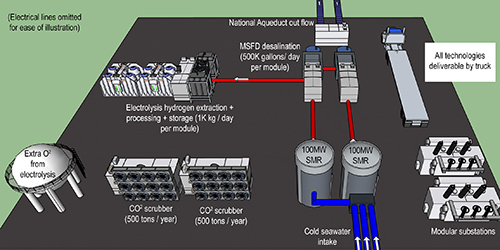

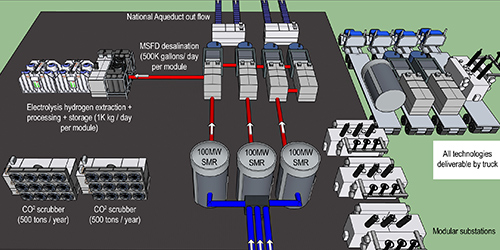

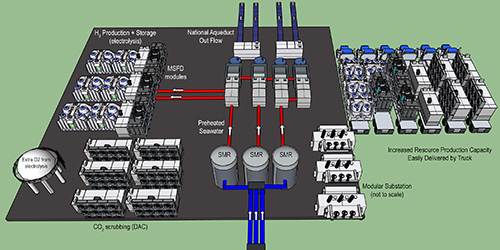

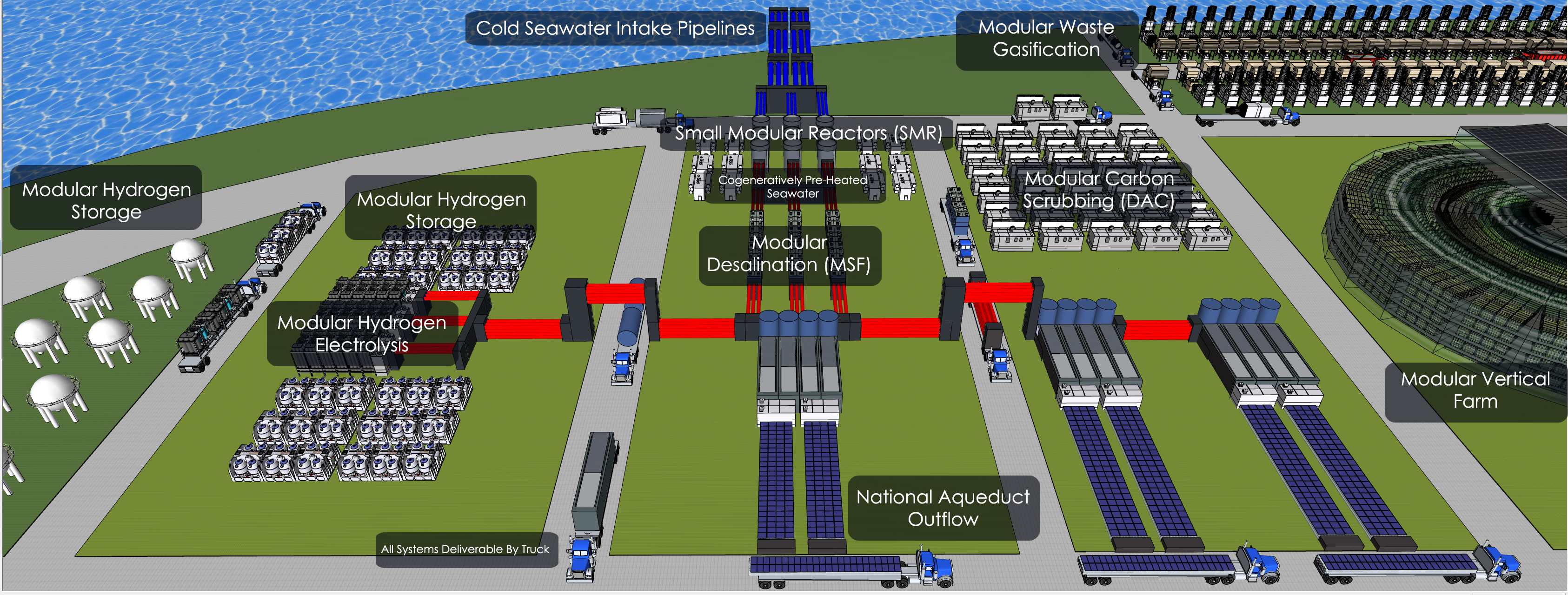

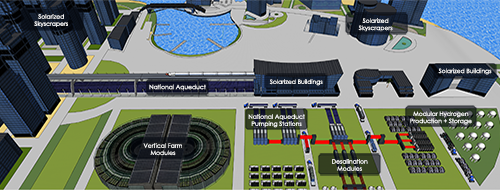

By designing power and resource infrastructure to be modular and standardized, cogenerative design can be included in every applicable step of system engineering. And as these systems can be mass produced at scale, cogenerative applications can be a standard feature of power generation. As a result, power infrastructure can not only be rapidly deployed and scaled, but also automatically leveraged to produce vital resources and perform auxiliary functions:

- Preheating seawater for large-scale desalination

- Powering hydrogen production through electrolysis

- Powering waste recycling through plasma gasification

- Powering carbon capture devices

- Powering indoor farms that are irrigated with desalinated seawater

Yet by modularizing these concepts into rapidly deployable systems, energy and resource infrastructure can be acquired and deployed by localities with minimal expertise in infrastructure development.

It is a significant feat to deploy a power plant today, or desalinate seawater, or produce and capture hydrogen - or recycle waste with a plasma gasifier. Each of the technologies that perform those functions today carry immense cost, engineering and power requirements. It's not something most municipalities can do by their own volition. Usually, such deployments require substantial investment from private utilities or government at a state/provincial or federal level.

Conversely, deploying energy and resource modules can be performed with far greater ease - effectively a truck delivery and site inspection. The complexities and engineering nuances of each system are still present, but they're wholly contained within the module - they don't extend into the module's ability to operate or perform its designed task. Few of us for example know how to build a light bulb, or a battery, or a computer monitor. We just get one and plug it in. Under this approach, any municipality could do the same with power and resource infrastructure that automatically satisfies a wide array of social needs.

The end result of this strategy to design power and resource systems to work off these core principles - and share waste energy to maximize their operational effectiveness in a cooperative environment - is a self-reinforcing ecosystem that provides the technical means to generate resources long past the point of need. Electricity, fuel, water, food and ultimately building materials can be produced to effectively unlimited scales because they are provided as a function of sustainable technology as opposed to unsustainable extraction.