Scarcity Zero's technologies generate a lot of energy, but the driving mindset behind their deployment is their ability to cooperate by design. This concept – the idea of diverting the waste energy of one technology to help power the functions of another – is commonly referred to as “cogeneration,” or “Combined Heat and Power” (CHP). But it hasn't really been a central component of past power plant design, and has only recently started to gain prominence.[1] In general, our current power infrastructure just “there,” decentralized, ad-hoc systems that are each custom-designed and built to order. They rarely work together.[2] They barely talk to each other.[3] They are built with non-standardized components and powered by non-standardized fuels.[4] Just as importantly: the energy they generate is usually devoted only to powering electric generators, any excess is written off as “waste” instead of used for auxiliary or offsite functions.

This is a squandered opportunity on a monumental scale.

Most power plants today have an efficiency of around 33%.[5] This means 67% of their generated energy is discarded in the form of heat that either dissipates into the surrounding air or is absorbed into the ground. That’s more than twice the energy used to generate electricity in the first place. If we’re going to build an advanced and clean energy future, we must improve the efficiency and utility of our power infrastructure over the long-term.

The problem? Entropy and thermal loss are unavoidable byproducts of energy transfer – which means we’re probably never going to be able to build power plants that operate at superb levels of efficiency. But we can harness waste energy to power auxiliary functions at low additional cost. This is something Scarcity Zero seeks to employ at the design stage so that every aspect of power-generation is engineered to maximize cogeneration from the ground-up. And not just within a given facility, either, but also externally to other facilities that could be modularly integrated within an indefinitely scalable standard.

This writing commonly refers to these facilities as “CHP Plants” (Combined/Cogenerative Heat and Power), but their defining characteristic is simply a deployment of energy technologies designed to maximize efficiency and operational capability by leveraging waste energy for other useful applications.

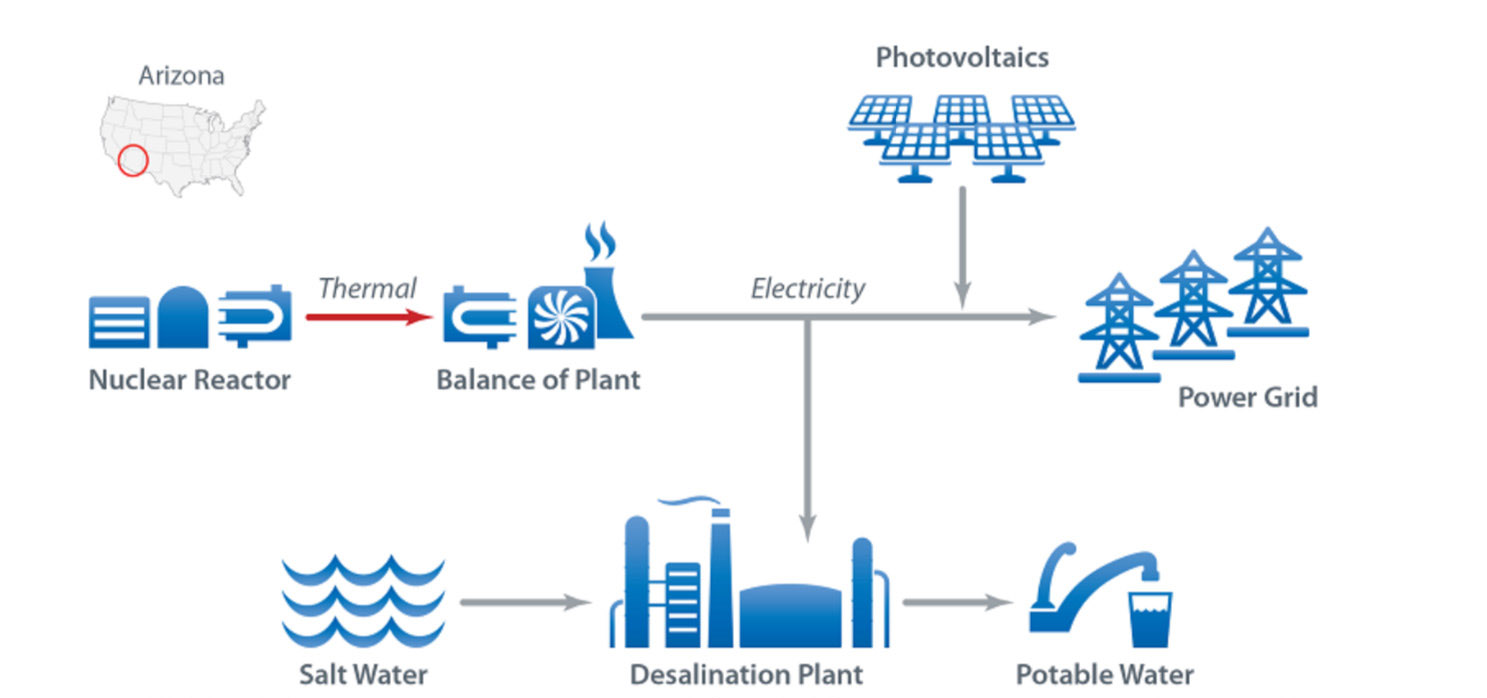

While this design is significantly more aggressive than even our most ambitious approaches to energy efficiency, it is not inventive in and of itself, and has several proven demonstrations of its concepts within both power generation and manufacturing.[6] One notable example is the National Renewable Energy Laboratory’s REopt™ model (Renewable Energy Integration & Optimization), which is designed to identify renewable and/or energy efficiency opportunities within power infrastructure. One of their flagship projects in Arizona (home to the nation’s largest nuclear reactor)[7] involved the integration of light-water nuclear with renewables to efficiently desalinate seawater into hydrogen.[8]

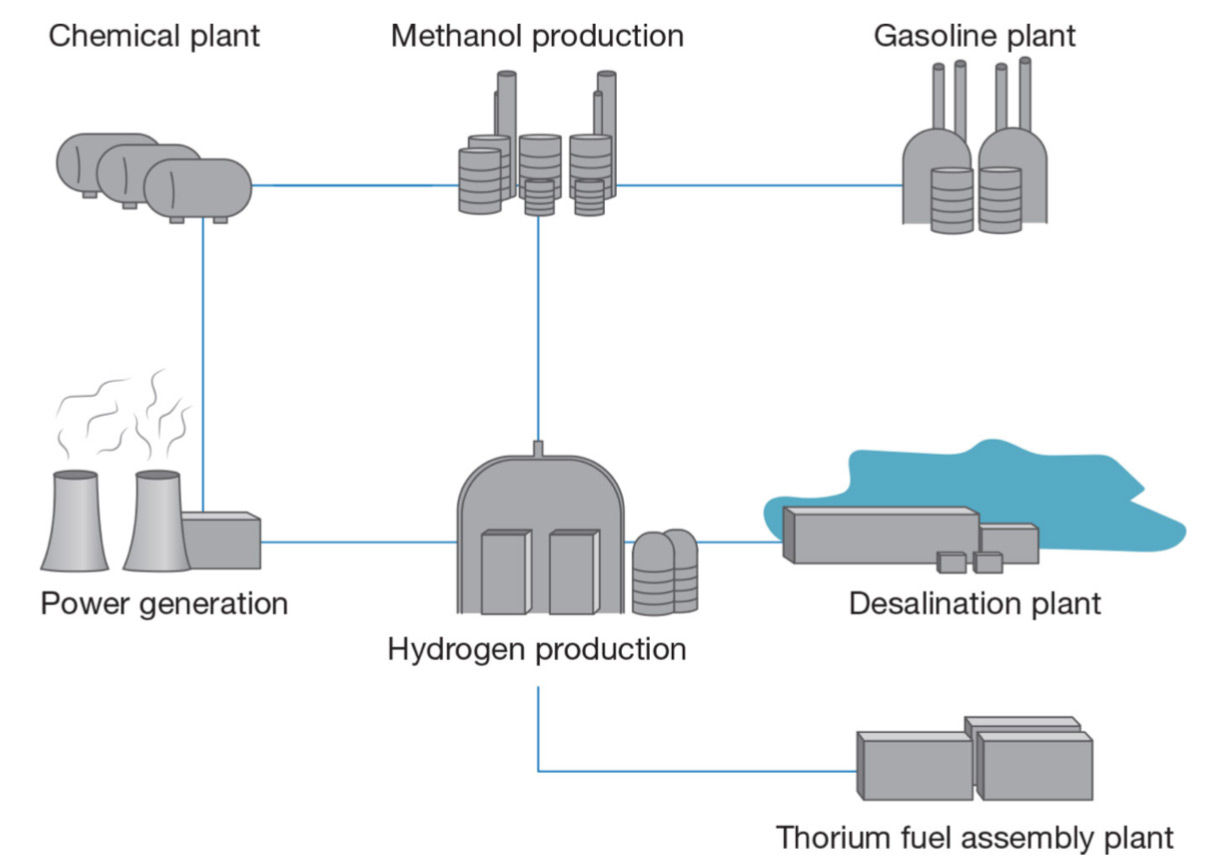

Another example is China’s TSMR project in Gansu province that we reviewed in Chapter Four. Their cogenerative deployment leveraged up to 100 megawatts of clean energy to power resource-producing systems within fresh water, hydrogen fuel and chemical hydrocarbons.10 - [11]

Russia’s thorium project conducted by their School of Nuclear Science & Engineering of Tomsk Polytechnic University further leverages cogeneration to desalinate seawater into fresh water and hydrogen fuel.[13] Cogeneration has also been leveraged on varied scales with other energy technologies[14] and has been committed into official policies of the European Union[15] and the UK[16] that generally require its inclusion to participate in energy tax incentives.[17] The underlying benefit of cogeneration, therefore, is both proven and by itself isn’t especially novel as applies to energy generation.

But cogeneration today – even if applied to strong effect – still reflects the same foundational shortcomings of our current energy schema. Each effort looks for practical – yet piecemeal – improvements within unique, ad-hoc systems that are designed and implemented as such. Even if NREL’s REopt engineers retain the best tools and brightest minds in the world, everything they do for one application in one area will have to be completely re-done from scratch in another because the nature, capabilities, and limitations of the technology deployment hinge on energy systems that are essentially made to order.

By leveraging today’s manufacturing capabilities to mass-produce identical power-generating systems that are modular and standardized, Scarcity Zero seeks to promote an energy mindset that’s cogenerative-first. This means energy technologies are designed first – from blueprint to integration – to work cooperatively with others on a modular standard. That, then, makes the framework indefinitely scalable because identical power modules can be extended, integrated and/or swapped on-demand.

This helps change the fundamentals of the energy question from “how can we identify individual efficiency improvements within unique power-generating systems” to questions both more practical and expansive in vision.

For example, let’s say we were to ponder the following tasks:

- What would be required to build a power facility in mid-coastal California that generates 300 megawatts of electricity, desalinates 40 million gallons of seawater and produces two metric tons of hydrogen per day?

- With that known, how easily could we upgrade that facility’s desalination capacity to 60 million gallons, add on another ½ ton of hydrogen production and 100 megawatts more electricity?

- In case the upgrades in task #2 exceed an allocated budget, what deliverables would respectively meet 35% and 75% of this target?

- How much land would this require at what size of building envelope and what terrain limitations would apply?

- All aspects considered, what’s the overnight cost of these deployments with a high degree of certainty – plus or minus no more than 5% - all regulatory and permitting aspects considered?

In a world where energy systems are unique and made to order, the presence of these very questions sustains the business models of global consulting conglomerates. Their answers take months to derive and cost millions of dollars.

Yet in a world where capabilities of modular, mass-produced systems are known clearly, and their deployments both integrate and scale with others by design, answering these questions becomes far easier.

The unknowns are removed from the equation because each energy system is model-identical in similar application to a D-cell battery – and can couple, swap or decouple from others just like the very same. Everything from power requirements, performance specifications to product lifetime and physical footprint can be granulized in database tables that could be used to generate dynamic reports with the click of a mouse.

While the engineering complexities of each system of course remain, they’re also contained within the module. They do not permeate into the module’s capabilities or connection interfaces. Nor do they need to. Few of us know how to design or build a lightbulb, battery, USB hard drive or computer monitor, for instance.

We simply know how it’s supposed to work and how to replace it if it doesn’t.

And, if we want a second one, simply get a second one and plug it in. This is how the world of technology works in nearly every commercial sector. A rare exception is power-generation.

The time has come for that to change.

As applicable to Scarcity Zero, we’ll take a brief overview of how the concept of cogeneration would apply to CHP Plants.

Every technology within the framework deals with electricity, heat, and/or water. When these technologies are deployed in close proximity to one another, they can easily be tied together to harness waste energy.

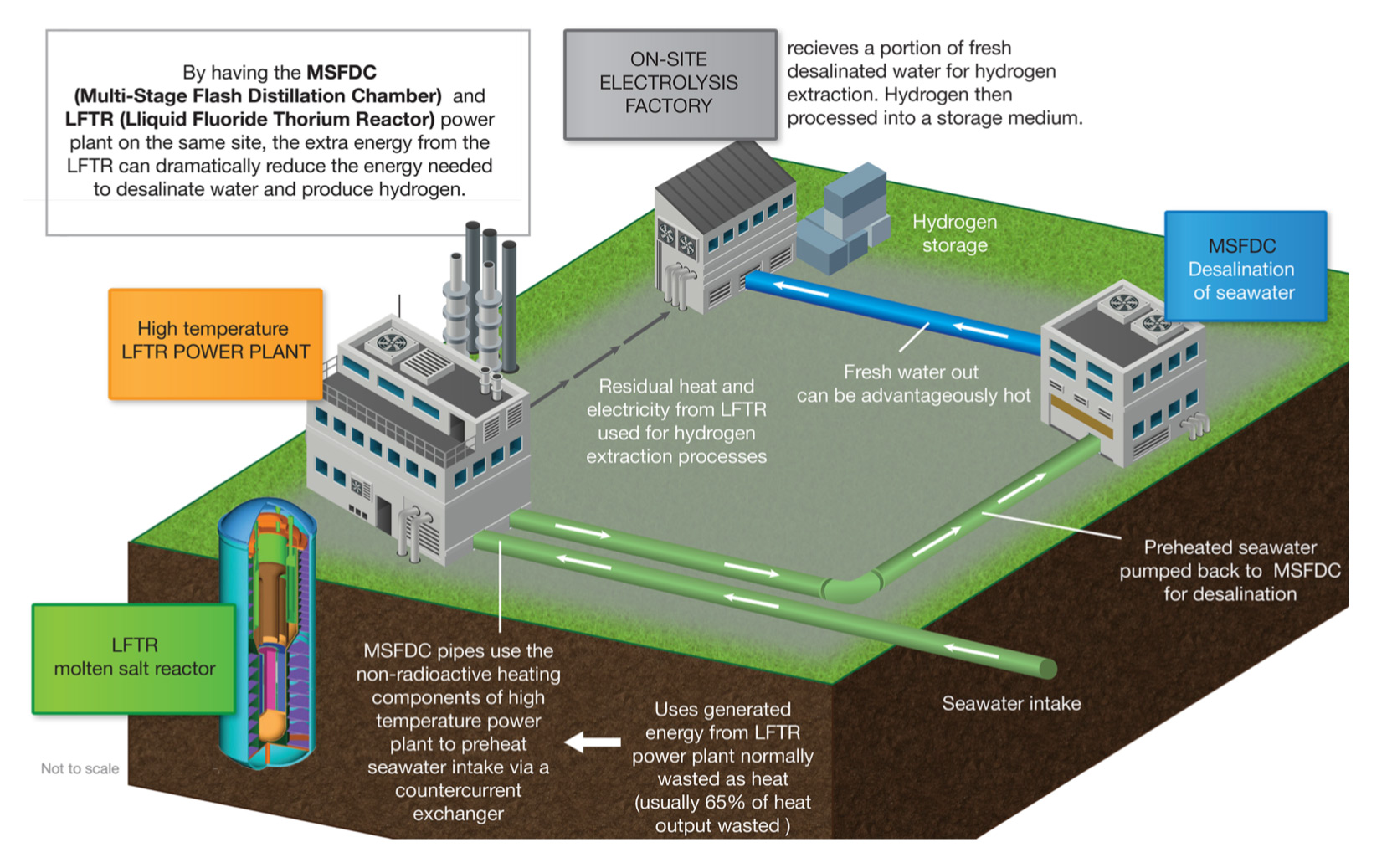

The central technology behind CHP Plants are Liquid Fluoride Thorium Reactors (LFTRs). As far as power plants go, LFTRs get hot – quite hot – (900 °C / 1,600 °F).[18] As the reactor's heat exchangers are well-separated from anything radioactive and its electric generator is driven by an inert helium loop, their waste heat can be harnessed as central energy source for secondary functions.

The first function is seawater desalination.

Normally, a Multi-Stage Flash Distillation (MSFD) facility counterflows waste hot brine with cool seawater to preheat it for desalination, recycling energy in the process. But by directly integrating seawater intake with the heat exchangers of LFTRs beforehand, the seawater can be brought to a boil before it even reaches the facility. This increases efficiency in both systems and translates to cost savings. Further, it sterilizes any microbial life within the seawater – further preventing concerns with the aquatic transfer of invasive species.

The second function is hydrogen production, as there is already an ample supply of heat, electricity, freshwater and electrolyte (ocean salt) on site to extract hydrogen into fuel or base supplies for synthetic materials.

The third function is to use excess energy for atmospheric scrubbing of greenhouse gasses and air pollution, and as we’ll review later in Chapter Ten, waste processing via plasma gasification.

This becomes especially important in contexts of addressing climate change, because it is the most direct and effective tool we have available to physically remove greenhouse emissions already present in our atmosphere – and perhaps the most vital method available to reduce the circumstances fueling an inexorably warming planet.[19]