Technology has brought us the litany of conveniences that define our modern era, but with these conveniences come increased waste that has proven deeply challenging to manage.[1] We’ve taken several approaches to get ahead of our growing waste problem: burying it in landfills, attempting to recycle old materials into new materials, “downcycling” materials into usable products (such as making park benches from shredded plastic bottles),[2] or simply burning it.[3] But none have truly succeeded in managing this issue on a global scale.

Scarcity Zero intends to change that. While it’s true that a goal of the framework is improving our ability to recycle things like plastics from the design stage, recycling complex polymers is inherently difficult.[4] While getting rid of single-use plastic products is a laudable goal, it ultimately does little to turn the tide of our monumental waste accumulation.[5] Ultimately, when we consider the extent of waste across the globe,[6] this problem seems impossibly daunting, no matter how sophisticated our technology becomes.

Yet the long-term survival of our environment requires of us to present a solution nonetheless - one that must be massive and immediate, effective and achievable – and all on a global scale.

There presently aren’t many technologies that can meet these requirements, but one called plasma gasification can.[7]

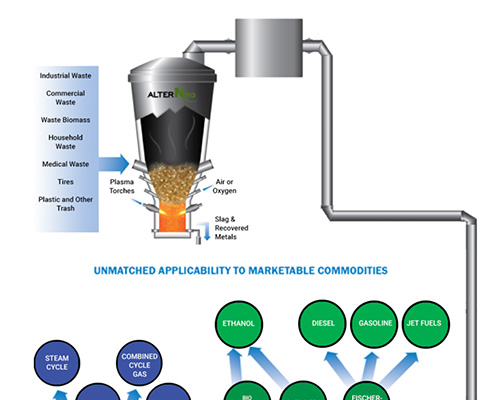

In concept, the “gasification” of waste isn’t much different than incineration – simply setting it on fire as humanity has done for millennia. But gasification uses a high-intensity electric current to create a plasma – an ultra-hot state of ionized gas – to separate trash into two separate states: the first, a material known as “syngas” that can be used as a fuel in several important applications, as shown on the following diagram. The second is an inert slag that can be used to make other useful materials like concrete, roads and insulation.[8]

Plasma gasification itself can also be harnessed as a potent source of energy, which can be used to both sustain its electric current and power other processes.[9] Normal incineration requires fuel and works at much lower temperatures, leaving behind harmful byproducts that present dangers to both public health and the environment.[10] Gasification avoids these issues completely.[11]

| Plasma Gasification | Incineration (burning) | |

|---|---|---|

| Temperature | High temperature, 1,400-1,600 °C | Medium heat (870-1200 °C) |

| Emissions | Does not create air pollutants | Allows toxic atmospheric pollutants to form. |

| Byproducts | ~99% of waste material becomes usable material. | ~30% of the waste material remains as toxic ash. |

| Useful Products | Syngas and an inert slag which is used in building materials and roads. | None. Incineration is among the most expensive and polluting methods of waste management. |

| Power | Generates power. | Requires fuel. |

Plasma gasification is an integral part of Scarcity Zero, that when partnered with other technologies in the framework, brings sophisticated waste management to any energy-generating ensemble. This capability is vital to a clean energy future because it enables us to not only process the immense volumes of trash our civilization has accumulated and littered throughout our environment, but also generate power from doing so as a side benefit.[13]

As this capability can further be paired alongside other cogenerative aspects of a modular and standardized energy framework, its application can be engaged across multiple important contexts: ocean trash removal, urban waste management and large-scale road construction using waste slag - helping to both clean, power and build our society in the same footprint.[14]

Intelligent Recycling

We build thousands of products on an industrial scale today, but once those products become obsolete, the materials used in them have often not been recycled or repurposed outside of scrap yards. Engineering and financial limitations, difficulties with transporting materials to recycling locations, extant systems with which to recycle them, and the energy necessary to power those systems are all limiting factors. Yet in a society powered by Scarcity Zero, we can take a sophisticated machine, strip out non-recyclable materials and send them off for plasma gasification, and extract recyclable substances that remain – retaining them for use elsewhere in manufacturing and fabrication.

In addition to powering a Circular Economy, this also gives us novel capabilities when rethinking our approach to manufacturing and recycling.

There are thousands of products today that are simply too complicated to be cost-effectively recycled. Consequently, once discarded they are often thrown in landfills. Wind turbines, solar panels, consumer electronics, aircraft fuselages and vehicle chassis are examples of a far longer list.[15] Yet Scarcity Zero's reduced energy and material costs, along with more sophisticated manufacturing approaches, can grant us capabilities to improve our manufacturing processes to build products that can be disassembled, recycled and/or upgraded in a modular capacity.

For example: instead of a vehicle going to a scrap yard once it gets old, we could instead engineer that vehicle to be stripped down to its basic components by a factory and refurbished into a newer model – a concept that could be applied to essentially any product.

This form of recycling ultimately benefits both consumers and manufacturers. It gives consumers the ability to exchange obsolete models for credit towards a newer model and reduces the expenses and sweat equity manufacturers pay to acquire materials and create products. These benefits contribute to cost savings for both parties, and also increases the agility of our manufacturing prowess by allowing us to do more with what we have presently.

There are of course standouts within our society that seek to achieve this goal already, but increasing the number of companies that do so alongside advances in energy generation and material procurement increases the efficacy of this recycling method – promoting its adoption within a greater share of market sectors.

This further affords a reduced waste footprint. Drastically improved waste management through gasification, an abundant supply of cheap energy, indefinite supplies of synthetic materials, and deconstruction-focused engineering substantially reduces the waste throughput of manufacturing processes and how we think of discarded products. With a society powered by Scarcity Zero, we wouldn’t build as many products at the expense of the environment, nor would we build products that are destined for landfills at the design stage. By upgrading and reconnecting our energy production, material procurement, and manufacturing and recycling processes, the lifecycle of a product is contained from start to finish – reducing nature’s presence in the equation.

This allows the achievement of three vital goals:

- With Scarcity Zero, it’s much easier to make next-generation synthetics that can outperform even the most advanced materials we have today – synthetics that we can use to build and improve practically anything.

- Under the same capabilities, we can dispose of waste and recycle products far easier and at greater scale than we can at present.

- With goals #1 and #2 met, we can now design systems and products to eventually be disassembled, repurposed and/or modularly upgraded - turning consumer products into longer-term investments instead of one-use discardables.

Combined with computer-aided manufacturing methods like additive/3D printing, this can transform the way our society manufactures products, and allows us to be more precise and sustainable through what we build, how we build it, and how we recycle it once the product eventually breaks down through a natural end of life cycle.